Now available outside the ITAR room for the first time! We spared no expense or effort to provide you with a panorama bridge for PVS14 night vision devices.

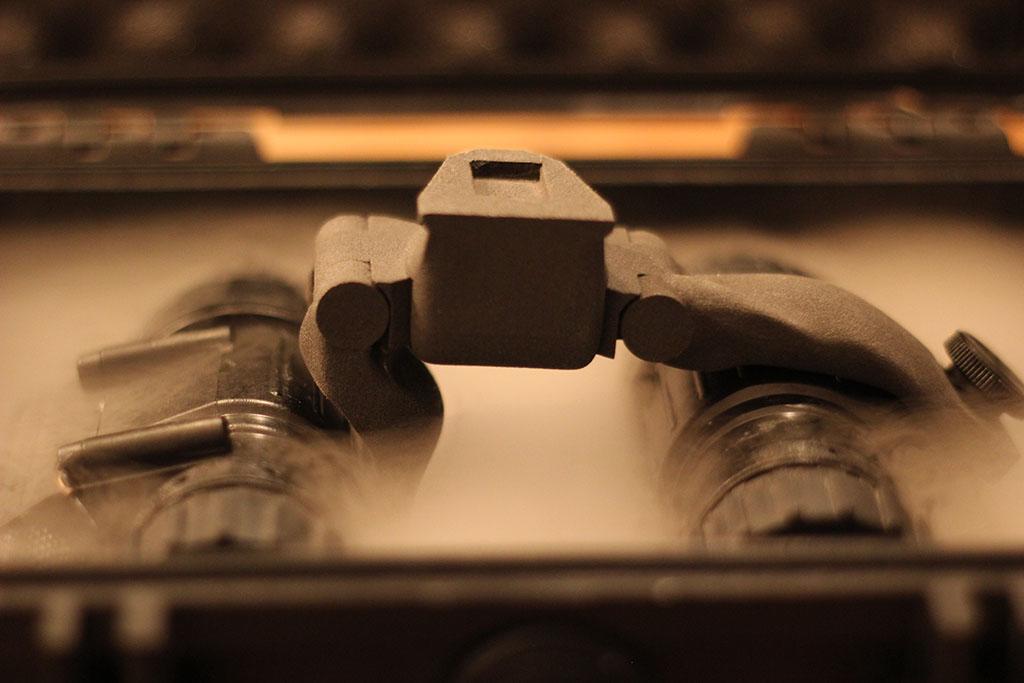

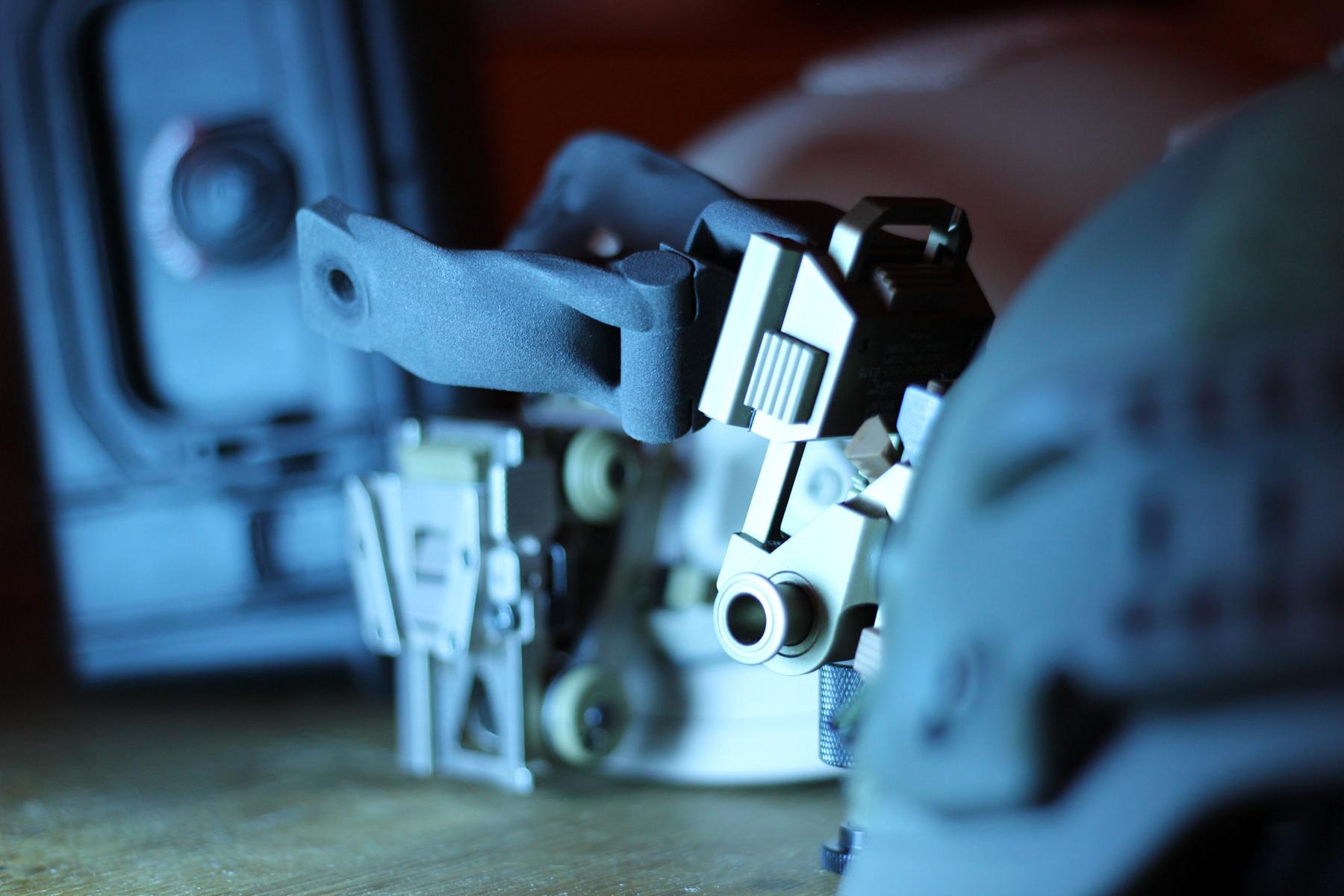

In cooperation with professional users, our engineers have developed a dual night vision device holder with which it is possible to expand the so-called field of view (FoV). Normal night vision devices from the binocular range have a field of view between 30 and 50 degrees. With our WIDE VIEW Bridge, which is unique in Europe, we can expand this field of view (FoV). A field of vision of up to 70 degrees is possible here. The aim here is not to copy the image of a GPNVG QuadEye, but rather the WIDE VIEW Bridge enables the usual “pipe effect” to be improved by WIDE VIEW: seeing the world in a panorama is simply more beautiful.

We offer professional users an interface so that they can carry out their tasks unhindered. Due to the modularity, it is possible to work adapted to the situation. In addition to the WIDE VIEW function mentioned above, our bridge can also be used as a “normal” binocular dual bridge for PVS14 devices. Should the respective order situation require you to expand your personal field of vision (e.g. in narrow spaces or when driving a vehicle), our WIDE VIEW Bridge can be expanded in your field of vision in a few simple steps.

You currently only use one PVS14 NOD and are considering getting a second one to use our WIDE VIEW function? No problem! For those who are undecided, there is the possibility of using our WIDE VIEW Bridge as a monocular solution. To do this, it is possible to dismantle the arm that is not in use or, even better, to fold it up. Caution! Please note: in order to offer the best possible quality, we use, among other things, specially coated slide bearings. This ensures a self-lubricating freedom of movement for the arms. In addition, the screws are precisely fixed with a torque wrench. We therefore recommend, if possible, to leave the arms in one position instead of dismantling them when not in use.

Material also means weight – that’s why we decided on high-performance plastic and use the so-called Selective Laser Sintering (SLS) process here. Here, plastic powders are fused with a laser with a tolerance of 0.3mm – so we can offer a sustainable and precise product and at the same time keep costs low.

All parts used have been designed, developed and produced in Germany – here we can also pay attention to our ecological footprint and rely on short transport routes.